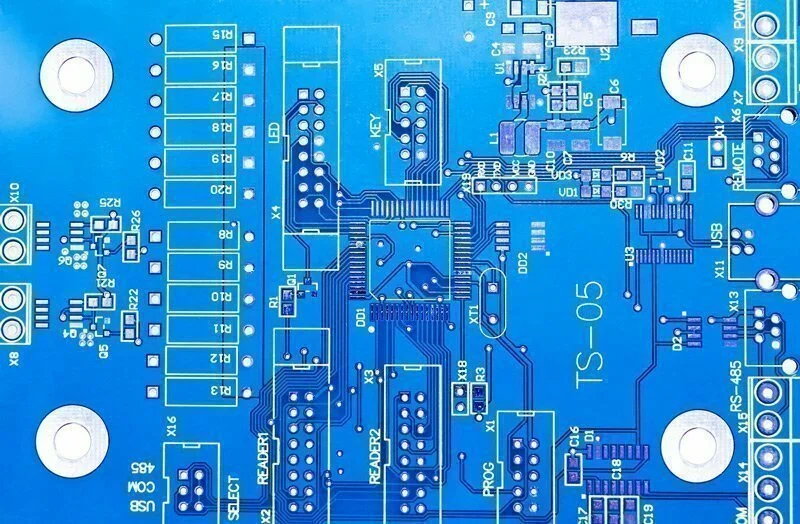

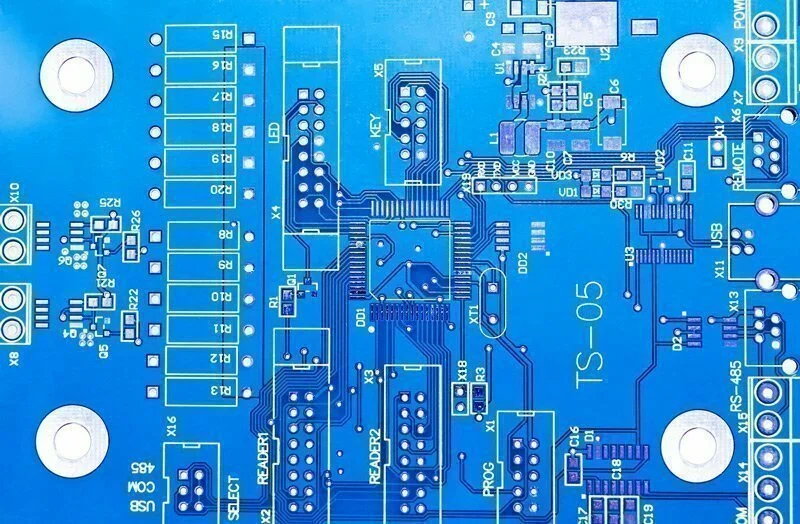

Applications of HDI PCBS span a wide range of industries, demonstrating their significance in achieving space-efficient, high-performance electronic solutions. These advanced circuit boards are instrumental in the development of compact electronic devices, including smartphones, tablets, and laptops. Furthermore, HDI PCBs play a pivotal role in medical equipment, automotive electronics, aerospace systems, telecommunications devices, wearable technology, and industrial applications. Their ability to facilitate miniaturization, maintain high signal integrity, and support complex functionalities makes them indispensable in the design and manufacturing of cutting-edge electronic products across diverse sectors.The following types of applications benefit the most from the use of HDI PCBs:

1. Mobile Devices:

Smartphones and Tablets:** HDI PCBs are widely used in mobile devices where space is a critical factor. These boards allow for the integration of complex functionalities in a compact form factor.

2. Consumer Electronics:

Laptops and Ultrabooks:HDI technology is essential in the design of slim and lightweight laptops where efficient use of space is crucial.

Digital Cameras:** HDI PCBs are beneficial for digital cameras, enabling the creation of smaller and more sophisticated imaging devices.

3. Medical Devices:

Medical Imaging Equipment: Devices such as ultrasound machines, CT scanners, and MRI machines often utilize HDI PCBs to achieve compact designs without compromising on performance.

Implantable Medical Devices:** HDI technology allows for the miniaturization of components, making it suitable for implantable medical devices where space is limited.

4. Automotive Electronics:

Advanced Driver Assistance Systems (ADAS):** HDI PCBs are used in the development of compact and high-performance electronic components for ADAS applications.

In-Car Infotainment Systems: The space constraints in vehicles make HDI PCBs advantageous for infotainment systems and other on-board electronics.

5. Aerospace and Defense:

Avionics:HDI PCBs are employed in avionic systems where reducing weight and maximizing space are critical for fuel efficiency and performance.

Military Electronics:Compact and high-density designs are important in military applications, and HDI PCBs are well-suited for meeting these requirements.

6. Telecommunications:

Networking Equipment:** HDI PCBs are used in routers, switches, and other networking equipment to achieve high-speed data transmission and compact designs.

Wireless Communication Devices:** Compact and high-performance PCBs are essential in devices like base stations and wireless communication modules.

7. Wearable Devices:

Smartwatches and Fitness Trackers:** The small form factor of HDI PCBs is ideal for wearable devices where space is limited, and energy efficiency is crucial.

8. Industrial Electronics:

Control Systems:HDI PCBs are used in industrial automation and control systems where compact designs and high reliability are important.

Test and Measurement Equipment: Precision equipment benefits from the enhanced signal integrity and reduced footprint provided by HDI technology.

In summary, any application that requires a high level of miniaturization, increased functionality, and improved electrical performance can benefit from the use of HDI PCBs. These boards enable the development of compact, lightweight, and high-performance electronic devices across various industries.