Electronics constantly shape our world, continuously evolving and introducing innovations that turn what we once deemed impossible into something attainable. At the epicenter of this tech transformation is a mighty, yet often overlooked component: the Printed Circuit Board (PCB). Custom PCB production isn't just manufacturing; it's an art that perfectly aligns with the unique visions of creators, engineers, and tech enthusiasts. This exposé takes you through the fine details of custom PCBs, highlighting why and how they’re reshaping the industry.

Consider Printed Circuit Boards as the circulatory system of electronic apparatuses—they create a nexus for parts to sync and systems to harmonize. But when the standard PCB doesn't suffice, custom PCBs step in, sculpted to the exact specifications of an application. This bespoke approach optimizes not just the PCB, but the device itself, refining its efficiency, form factor, and potency.

The genesis of a custom PCB is a symphony of precise craftsmanship and pioneering design. It starts with an idea, matures into a schematic, and becomes a physical entity with the potential to advance technology.

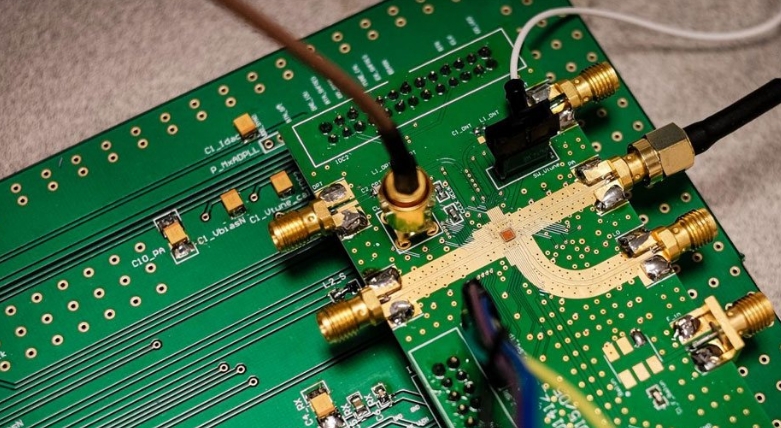

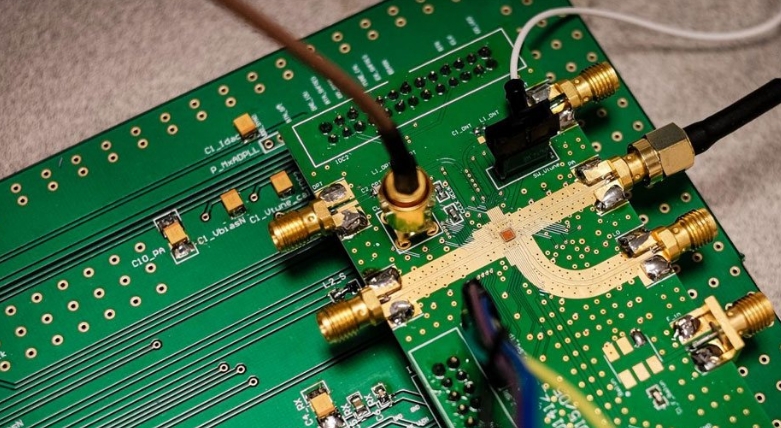

Design and prototyping go hand in hand. Engineers employ cutting-edge programs to design a PCB layout—a complex map of electrical routes consisting of traces, pads, and vias. After the schematic is drawn, a prototype breathes initial life into the concept, laying the foundation for rigorous evaluation and refinement.

Material selection is pivotal; it's the difference between a functional PCB and a piece of art that masters the electrical current. Commonly, FR4 serves as a sturdy canvas while copper lines weave the electrical connections in place.

Production is a study in precision, involving etching, drilling, layering, and more. It’s where technology meets craftsmanship, ensuring the digital design manifests into a tangible, high-functioning PCB.

Next, components find their home on the board through the genius of surface-mount or through-hole mounting techniques. The process can be automated for efficiency, with a close eye on detail, ensuring no solder joint is misplaced, and no component is overlooked.

A custom PCB must survive the gauntlet of testing—electrical validation ensures every circuit conversation is fluent, and each electronic exchange is pristine without any risk of shorting or miscommunication.

Innovation necessitates the pursuit of customization. Custom PCBs stand tall where generic solutions falter, particularly in specialized fields such as bespoke medical instruments, avant-garde aerospace tech, or personalized consumer gadgets. For designers, having the latitude to draft a PCB that is the glove to their project’s hand is nothing short of revolutionary.

Custom PCB production is deeply rooted in the soil of ambition and innovation. It doesn't matter if it's a fledgling startup or a titan of industry—the quest for electronics that embody the zenith of design and functionality relies heavily on these specialized PCBs. As the digital age unfolds before us, it's clear: the role of custom PCB production is more than vital; it's the very essence of the electronic renaissance.

If this journey through the electrical maze has piqued your interest or if you're on a quest for practical guidance in custom PCB production, you're encouraged to reach out to the titans of the industry, leaders who can help manifest your most bespoke electronic ambitions.