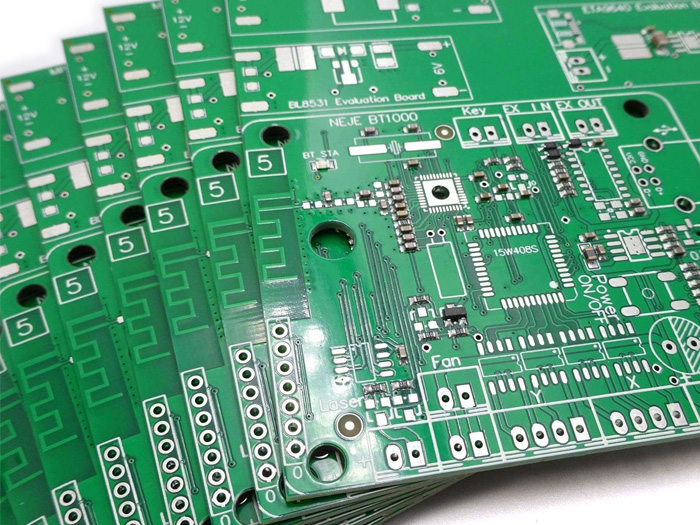

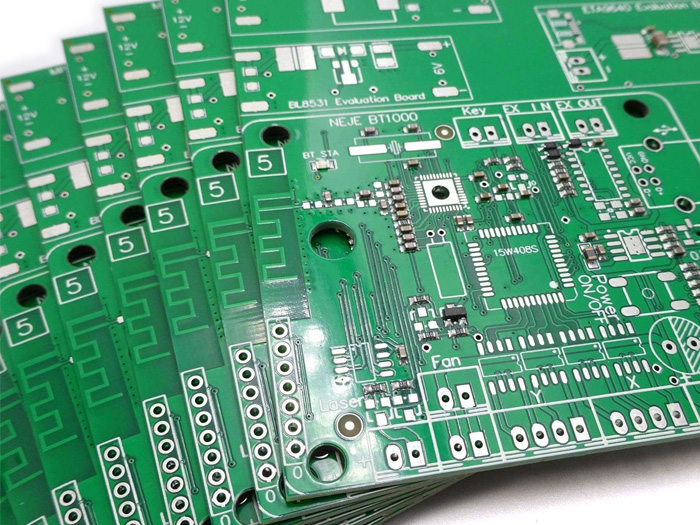

A custom PCB, or Printed Circuit Board, is a circuit board designed and manufactured to meet specific requirements of a particular electronic device or application. It is customized to fit the unique needs of a project, offering flexibility in terms of size, shape, component placement, and functionality. Here's how it differs from a standard PCB:

1.Tailored Design: Custom PCBs are designed to meet the specific requirements of a particular project. This includes considerations for the size and shape of the board, as well as the placement of components to optimize performance and functionality.

Unique Specifications: Custom PCBs are built with unique specifications, taking into account factors such as power requirements, signal integrity, thermal management, and any other specific needs of the electronic device.

2.Application-specific Features: Unlike standard PCBs that are designed for general use, custom PCBs often incorporate application-specific features. This could include specialized connectors, sensors, communication interfaces, or other components tailored to the intended purpose of the device.

3.Optimized Performance: Custom PCBs are engineered to deliver optimized performance for a particular application. This may involve minimizing signal interference, reducing power consumption, or meeting specific speed and reliability requirements.

4.Project Integration: Custom PCBs are integrated into a larger project or device, and the design process takes into account the overall system requirements and constraints to ensure seamless integration.

5.Cost Considerations: While custom PCBs offer tailored solutions, they can be more expensive to design and manufacture compared to standard PCBs. The cost is often justified by the benefits of optimized performance and functionality for the specific application.

6.Prototyping and Iteration: Custom PCBs may go through multiple prototyping and iteration phases to fine-tune the design and ensure it meets the desired specifications. This iterative process allows for refinement and improvement before final production.

In contrast, standard PCBs are mass-produced and typically used in a variety of applications without modification. They are more cost-effective for general purposes but may not provide the level of customization required for specialized projects or devices.