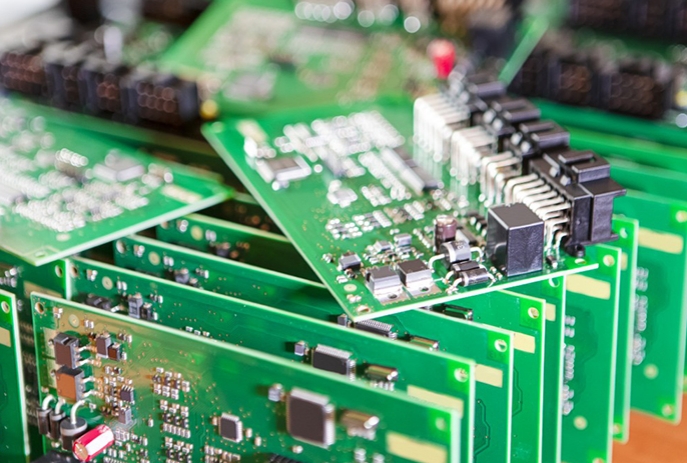

Circuit Card Assembly (CCA) is an important process in electronic devices. It involves putting together various electronic parts to form the intricate structure of printed circuit boards (PCBs). In this detailed guide, we will simply explain CCA. We want to inform you about the process of making electronic devices and share our valuable knowledge about it.

1. A CCA is like a whole circuit board assembly, with the board itself and all the electronic parts. On the other hand, a PCBA is just a circuit board with the parts attached to it.

2. CCAs are usually more complicated than PCBAs because they have both the board and the parts, and all the connections between them.

3. Electronic device manufacturers frequently include CCAs in the products they produce in large quantities, such as smartphones and laptops. These manufacturers strive to make these devices small and tightly pack various components together.

4. On the other hand, smaller quantities of devices, such as prototypes and custom designs, utilize PCBAs. These devices prioritize flexibility and ease of assembly.

So, in simple terms, a CCA is a completed circuit board with all the parts, while a PCBA is just a circuit board with the parts attached. High-volume devices use CCAs because they are more complicated, whereas lower-volume devices use PCBAs.

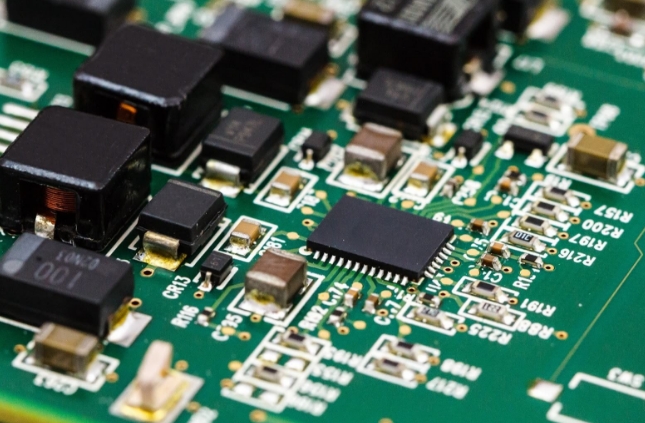

The following are some basic electronic components necessary for circuit assembly:

Resistors: People use resistors to control the flow of current in a circuit. They are available in a variety of values, from a few ohms to several megaohms.

Capacitors: People use capacitors to store electrical energy. They are available in a variety of values, from a few picofarads to several farads.

Inductors: People use inductors to store magnetic energy. They are available in a variety of values, from a few microhenries to several henries.

Diodes: Diodes allow current to flow in only one direction. A variety of applications use them, including rectifying AC current and protecting circuits from reverse current flow.

Transistors: Transistors amplify or switch electronic signals. They are available in a variety of types, such as bipolar junction transistors (BJTs) and field-effect transistors (FETs).

Integrated circuits (ICs):A single chip of semiconducting material produces tiny electronic circuits called ICs. ICs can comprise various electronic components, such as transistors, diodes, and resistors.

Depending on the specific application, circuit assembly utilizes a number of other electronic components in addition to these basic components. These components include:

Connectors: People use connectors to connect different parts of a circuit together. They are available in a variety of types, such as plugs, sockets, and headers.

Switches: Switches control the flow of current in a circuit. Various types of switches are available, including pushbutton switches, toggle switches, and rotary switches.

Fuses: Fuses guard circuits against overcurrent conditions. They come in a range of values, spanning from a few amps to several hundred amps.

Heat sinks: Electronic components use heat sinks to dissipate heat. Manufacturers usually make them out of metal, such as aluminum or copper.

These are just a few of the basic electronic components that are necessary for circuit assembly. The design of the circuit will determine the specific components needed.

These are just a few of the basic electronic components that are necessary for circuit assembly. The specific components that are needed for a particular circuit will depend on the design of the circuit.

After assembling the components onto the PCB, typically, the team tests the board to ensure its proper functioning. They can employ various test methods, including electrical testing, functional testing, and in-circuit testing.

Electronic components and PCB assembly are essential for the manufacture of a wide range of electronic devices, including computers, smartphones, televisions, and medical devices.

Here are some of the benefits of using electronic components and PCB assembly:

Reduced size and weight: PCBs allow for the miniaturization of electronic devices, making them more portable and easier to use.

Improved reliability: PCBs provide a stable and reliable platform for mounting and interconnecting electronic components.

Increased functionality: PCBs can be used to create complex circuits with a high density of components, enabling a wide range of functions.

Lower cost: PCBs can be mass-produced, which helps to reduce the cost of electronic devices.

Overall, electronic components and PCB assembly are essential for the development and manufacture of modern electronic devices.

A Circuit Card Assembly (CCA), also known as a Printed Circuit Board Assembly (PCBA), is a crucial component in electronic devices and systems. Its primary function is to provide an interconnected platform for electronic components to work together and perform specific functions within an electrical or electronic system. CCAs play several essential roles:

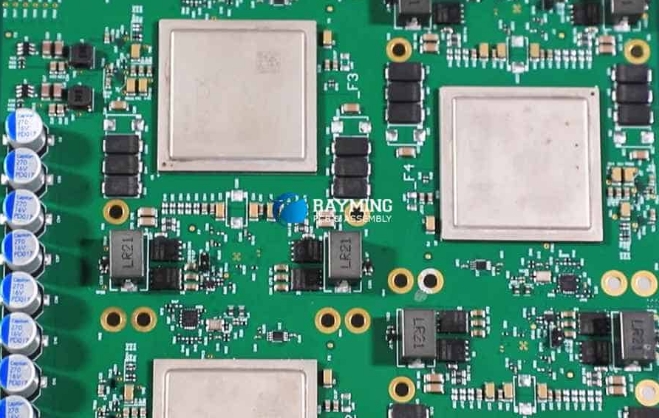

Component Mounting: CCAs provide a substrate (usually a printed circuit board or PCB) on which electronic components like resistors, capacitors, integrated circuits, and connectors are mounted. These components are soldered onto the PCB, establishing the necessary electrical connections.

Electrical Pathway: The PCB on a CCA is designed with conductive pathways, or "traces," that create an interconnected network of electrical pathways. These traces allow signals and power to flow between the mounted components, facilitating communication and functionality.

Signal Routing: CCAs facilitate the routing of signals between various components. They ensure that electrical signals reach the right components in the correct sequence, enabling the device to function as intended.

Power Distribution: CCAs also distribute power to the different components on the board. They manage the voltage and current distribution to ensure that each component receives the required power supply.

Mechanical Support: Beyond electrical functions, CCAs often provide mechanical support and protection for electronic components. They can house components in a structured and secure manner.

Interconnectivity: In complex systems, multiple CCAs can be interconnected to form more extensive electronic systems. This interconnectivity allows for the creation of larger, multifunctional electronic devices.

In summary, a Circuit Card Assembly is a central component in electronic devices, serving as the backbone for component mounting, electrical connections, signal routing, and power distribution. It enables the electronic device to perform its intended functions by coordinating the interactions between various components and ensuring that electrical signals and power are managed effectively.

The PCB assembly process typically involves the following steps:

PCB fabrication: This is the process of creating the PCB itself. It involves laminating layers of conductive material, such as copper, to a non-conductive substrate material, such as fiberglass. The copper layers are then patterned using a process called photolithography to create the desired circuit traces.

Solder paste application: Solder paste is a mixture of solder particles and flux. It is applied to the PCB pads where the components will be mounted.

Component placement: The electronic components are placed on the PCB, typically using a pick-and-place machine.

Soldering: The PCB is then heated to melt the solder paste and form a strong electrical connection between the components and the PCB. This can be done using a variety of soldering methods, such as reflow soldering or wave soldering.

Inspection: The assembled PCB is then inspected to ensure that all of the components are properly placed and soldered. This can be done manually or using automated optical inspection (AOI) equipment.

Testing: The assembled PCB is then tested to ensure that it is functioning properly. This can be done using a variety of test methods, such as electrical testing, functional testing, and in-circuit testing.

Once the PCB assembly process is complete, the PCB is ready to be installed into the final electronic device.

Here are some additional details about each step in the PCB assembly process:

1.PCB fabrication:

The first step in PCB fabrication is to create the inner layers of the PCB. This is done by laminating sheets of copper foil to a core material, such as fiberglass.

The inner layers are then patterned using a process called photolithography. This involves applying a photoresist to the copper foil and then exposing it to ultraviolet light through a photomask. The photoresist is then developed, which removes the exposed areas of copper foil.

The inner layers are then laminated together to form the multilayer PCB.

The outer layers of the PCB are then created using the same process.

2.Solder paste application:

Solder paste is applied to the PCB pads using a stencil. The stencil is a metal sheet with holes that are aligned with the PCB pads.

The solder paste is applied to the stencil using a squeegee.

The PCB is then placed on the stencil and heated. The heat melts the solder paste and causes it to flow through the holes in the stencil and onto the PCB pads.

3.Component placement:

The electronic components are placed on the PCB using a pick-and-place machine.

The pick-and-place machine uses a vacuum nozzle to pick up the components and place them on the PCB.

The components are placed on the PCB according to a pre-programmed placement file.

4.Soldering:

The PCB is then heated to melt the solder paste and form a strong electrical connection between the components and the PCB.

This can be done using a variety of soldering methods, such as reflow soldering or wave soldering.

Reflow soldering involves heating the PCB in a convection oven. The heat melts the solder paste and causes it to flow and form solder joints.

Wave soldering involves passing the PCB over a wave of molten solder. The solder wave melts the solder paste and forms solder joints.

5.Inspection:

The assembled PCB is then inspected to ensure that all of the components are properly placed and soldered.

This can be done manually or using automated optical inspection (AOI) equipment.

AOI equipment uses cameras to inspect the PCB for defects, such as missing components, misaligned components, and solder bridges.

6.Testing:

The assembled PCB is then tested to ensure that it is functioning properly.

This can be done using a variety of test methods, such as electrical testing, functional testing, and in-circuit testing.

Electrical testing involves measuring the electrical properties of the PCB, such as resistance, capacitance, and inductance.

Functional testing involves testing the PCB to ensure that it is performing its intended function.

In-circuit testing involves testing the PCB while it is still in the circuit. This can be done using a bed of nails tester or a flying probe tester.

Once the PCB assembly process is complete, the PCB is ready to be installed into the final electronic device.

There are many different types of circuit card assemblies (CCAs), each with its own unique design and purpose. Some of the most common types of CCAs include:

Single-sided CCAs: These are the simplest type of CCA, with components mounted on only one side of the board.

Double-sided CCAs: These CCAs have components mounted on both sides of the board, allowing for a higher density of components.

Multilayer CCAs: These CCAs have multiple layers of conductive material, allowing for even higher component density and more complex circuit designs.

Rigid CCAs: These CCAs are made from a rigid material, such as FR-4 or metal-backed epoxy.

Flexible CCAs: These CCAs are made from a flexible material, such as polyimide or polyester.

Rigid-flex CCAs: These CCAs combine both rigid and flexible materials, allowing for complex designs with high component density.

CCAs can also be classified by their application, such as:

Consumer electronics CCAs: These CCAs are found in a wide range of consumer electronic devices, such as smartphones, tablets, and laptops.

Industrial CCAs: These CCAs are used in industrial machinery and equipment, such as robots and CNC machines.

Automotive CCAs: These CCAs are used in vehicles, such as cars, trucks, and buses.

Medical CCAs: These CCAs are used in medical devices, such as pacemakers and defibrillators.

Aerospace CCAs: These CCAs are used in aircraft and spacecraft.

CCAs are essential components in a wide range of electronic devices. By understanding the different types of CCAs available, you can choose the right CCA for your specific application.

Here are some additional types of CCAs that are worth mentioning:

Surface-mount technology (SMT) CCAs: These CCAs have components mounted directly to the surface of the board, rather than being inserted into holes.

Through-hole technology (THT) CCAs: These CCAs have components mounted through holes in the board.

Mixed-technology CCAs: These CCAs use a combination of SMT and THT components.

High-density interconnect (HDI) CCAs: These CCAs have a very high density of components, achieved through the use of fine lines and spaces.

Build-up CCAs: These CCAs are made by adding layers of conductive material to a core board.

The type of CCA that you choose will depend on the specific requirements of your application.

1. Electronic Components and the Heart of Assembly

At the core of electronic manufacturing lie electronic components, the fundamental units that power our devices. This article explores how these components come together in the intricate process of Circuit Card Assembly (CCA), shedding light on the essential role they play.

2. The Crucial Role of Reflow Ovens in CCA Manufacturing

In the realm of CCA manufacturing, the reflow oven takes center stage. This section delves into the significance of reflow ovens, unraveling their role in the assembly process and how they contribute to the seamless integration of electronic components.

3. IPC's Perspective: CCA vs. PCBA in Intellectual Property

The Intellectual Property Constituency (IPC) is a key player in safeguarding innovations. Focusing on the terms Circuit Card Assembly (CCA) and Printed Circuit Board Assembly (PCBA), this part explores how IPC utilizes these terms to protect intellectual property in electronic manufacturing.

4. PCB Assembly: The Blueprint for Electronic Devices

Understanding the printed circuit board (PCB) assembly process is pivotal. This section dissects the stages involved, emphasizing how the assembly process serves as the blueprint for the functionality of electronic devices.

5. Diverse Types of Circuit Card Assemblies

Not all CCAs are created equal. This segment categorizes and explores the different types of circuit card assemblies, emphasizing their variations depending on electronic device types, power supplies, and the assembly technologies employed.

6. SMT and BGA: Advancements in Surface Mount Technology

Surface Mount Technology (SMT) and Ball Grid Array (BGA) are revolutionizing the electronic manufacturing landscape. Delving into these cutting-edge technologies, this part elaborates on how they enhance the assembly process, particularly in the context of CCAs.

7. Automation Revolution: The Role of Automated Machines

Automated machines have become the backbone of modern manufacturing. This section highlights their pivotal role in the CCA process, emphasizing how automation ensures precision, efficiency, and high-quality assembly.

8. CCA Process Unveiled: Stages and Dependencies

Unveiling the intricacies of the CCA process, this part explores each stage, emphasizing dependencies and critical factors that influence the outcome. Understanding the journey from electronic components to the final product is paramount in appreciating the complexity of CCA manufacturing.

9. CCA vs. Printed Circuit: Making the Distinctions Clear

Clarifying the distinctions between Circuit Card Assemblies (CCAs) and Printed Circuits, this section provides a comparative analysis, underlining the unique attributes that set them apart in the electronic manufacturing landscape.

Circuit card assembly (CCA), also known as printed circuit board assembly (PCBA), is the process of assembling electronic components onto a printed circuit board (PCB) to create a functional electronic device. CCA is a crucial component of modern electronics, as it enables the creation of devices that are smaller, faster, and more reliable than ever before.

However, not all CCA manufacturers are the same. Choosing the right CCA manufacturer for your project can make a big difference in the quality, cost, and delivery time of your product. In this article, we will provide some tips on how to choose a CCA manufacturer that meets your needs and expectations.

Step 1: Understand Your Needs

Before you start looking for a CCA manufacturer, you need to have a clear idea of what you need from them. Some questions to ask yourself are:

What is the purpose and function of your device?

What are the specifications and requirements of your PCB design?

How many units do you need to produce and in what time frame?

What is your budget and how flexible are you on the price?

What are the quality standards and testing methods that you expect from the manufacturer?

Having a clear understanding of your needs will help you narrow down your options and communicate effectively with potential manufacturers.

Step 2: Conduct Research, Including Experience and Capabilities

Once you have defined your needs, you can start researching different CCA manufacturers and compare their experience and capabilities. Some factors to consider are:

How long have they been in the business and what is their reputation in the industry?

What are their areas of expertise and specialization?

What are their certifications and accreditations, such as ISO, UL, RoHS, etc.?

What are their equipment and technologies, such as automated component placement machines, flexible and rigid-flex circuit boards, high density interconnect (HDI) circuit boards, chip-on-board (COB) circuit boards, etc.?

What are their services and support, such as PCB layout design, engineering services, component sourcing, cable assembly, wire harnesses, box build, etc.?

You can find this information on the manufacturer’s website, online reviews, customer testimonials, industry directories, or by contacting them directly. You can also ask for samples or references of their previous work to evaluate their quality and performance.

Step 3: Take a Close Look at Quality Assurance and Testing Methods

Quality is a key issue when selecting the right CCA manufacturer. You want to make sure that your device is delivered as required and to the defined specifications without errors or defects. Therefore, you need to check the quality assurance and testing methods that the manufacturer uses, such as:

1.Bare board test: This test checks the electrical continuity and integrity of the PCB before the components are soldered onto it.

2.In-circuit test: This test checks the functionality and performance of the components and circuits on the PCB after the assembly process.

3.Functional test: This test checks the functionality and performance of the entire device after the assembly process.

4.Environmental test: This test checks the reliability and durability of the device under different environmental conditions, such as temperature, humidity, vibration, shock, etc.

You should also inquire about the manufacturer’s quality control policies and procedures, such as inspection, documentation, traceability, warranty, etc.

Step 4: Determine How Quickly Can You Receive Delivery

Another important factor to consider when choosing a CCA manufacturer is the delivery time. Depending on your project’s urgency and complexity, you may need to receive your product in a matter of days, weeks, or months. Therefore, you need to ask the manufacturer about their lead time, which is the time it takes from placing the order to receiving the product. You should also ask about their turnaround time, which is the time it takes from receiving the PCB design to delivering the finished product.

Some factors that can affect the delivery time are:

1.The availability and lead time of the components

2.The complexity and quantity of the PCB design

3.The type and level of testing required

4.The shipping method and destination

You should also ask the manufacturer about their flexibility and responsiveness in case of any changes or issues that may arise during the production process.

Step 5: Make Sure Reviews and Customer Support Are Solid

Finally, you should also consider the reviews and customer support that the CCA manufacturer provides. You want to work with a manufacturer that has a good reputation and a high level of customer satisfaction. You can find out about this by reading online reviews, customer testimonials, or industry awards that the manufacturer has received. You can also contact their previous or existing customers and ask for their feedback and recommendations.

You should also evaluate the customer support that the manufacturer offers, such as:

How easy is it to communicate with them and how responsive are they to your inquiries and requests?

How well do they understand your needs and expectations and how willing are they to accommodate them?

How transparent are they about their processes and progress and how often do they update you on the status of your order?

How helpful and friendly are they and how well do they handle any issues or complaints that may arise?

You want to work with a manufacturer that treats you as a valued partner and not just as a customer.

Choosing the right CCA manufacturer for your project can be a challenging task, but it can also be a rewarding one if you follow the steps and tips outlined in this article. By understanding your needs, conducting research, checking quality and delivery, and evaluating reviews and support, you can find a CCA manufacturer that can deliver a high-quality product that meets your specifications, budget, and deadline. If you need more help or guidance, feel free to contact us.