In the dynamic world of electronics, Printed Circuit Boards (PCBs) play a pivotal role in enabling the functionality of countless devices. PCB manufacturing involves a meticulous process that encompasses various stages, from design to production. This article provides an in-depth exploration of key aspects related to PCB manufacturing, assembly, and design.

1. PCB Manufacturing Overview:

PCB manufacturing is the backbone of electronic device development. It involves the production of Printed Circuit Boards, the foundational components that facilitate the interconnection of electronic components on a single board.

2. PCB Production and Fabrication:

The production phase includes PCB fabrication, where intricate designs are translated into physical boards. The fabrication process is crucial, ensuring the accuracy and precision of the final product.

3. Printed Circuit Board Manufacturing Process:

The manufacturing process involves several steps, including PCB etching, where unwanted copper is removed to create circuit traces. This step is essential for defining the electrical pathways on the board.

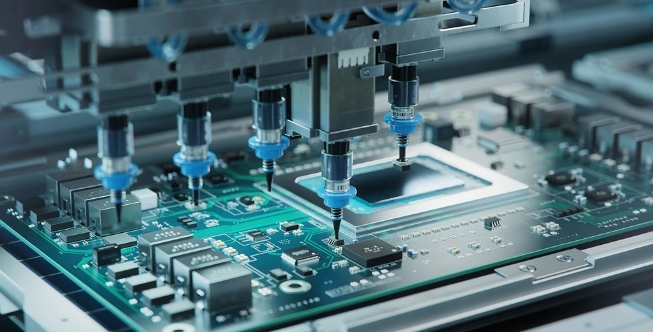

4. PCB Assembly and Prototyping:

PCB assembly is the stage where electronic components are mounted onto the board. Prototyping allows for testing and refinement before mass production, ensuring the design meets specifications.

5. Multilayer PCB and Quick Turn PCB:

Multilayer PCBs provide enhanced functionality by incorporating multiple layers of circuitry. Quick Turn PCB services offer accelerated production timelines, crucial for time-sensitive projects.

6. PCB Design and Manufacturing Integration:

Effective integration of PCB design and manufacturing is vital for seamless production. A well-designed PCB considers manufacturing constraints to optimize efficiency.

7. SMT PCB and THT PCB:

Surface Mount Technology (SMT) and Through-Hole Technology (THT) represent different approaches to mounting components on PCBs. SMT involves attaching components directly to the board's surface, while THT involves leads passing through holes in the board.

8. PCB Layout and Quality Control:

The PCB layout is the arrangement of components and traces on the board. Quality control measures ensure that each PCB meets stringent standards, minimizing defects and ensuring reliability.

9. RoHS Compliant PCB:

RoHS compliance is essential for environmentally conscious manufacturing. RoHS-compliant PCBs restrict the use of hazardous materials, contributing to a safer and greener electronic industry.

10. Electronic Manufacturing Services (EMS):

Electronic Manufacturing Services encompass a range of services, including PCB manufacturing, assembly, and testing. EMS providers play a crucial role in bringing electronic products to market.

11. PCB Testing and Etching:

Testing ensures the functionality and reliability of PCBs. PCB etching, as part of the manufacturing process, involves chemically removing unwanted copper to achieve the desired circuit patterns.

12. Surface Mount Technology (SMT) Advancements:

Advancements in SMT contribute to smaller and more efficient electronic devices. Miniaturization and improved reliability are key benefits of evolving SMT technologies.

13. Through-Hole Technology (THT) Innovations:

THT continues to be relevant, especially in applications requiring robust connections. Innovations in THT focus on improving durability and expanding its application range.

14. Prototype PCB Board Considerations:

When creating prototype PCB boards, factors like design validation, component compatibility, and manufacturability must be carefully considered for successful product development.

In conclusion, a holistic understanding of PCB manufacturing, assembly, and design is crucial for engineers, designers, and manufacturers alike. Keeping abreast of industry trends and technological advancements ensures the production of cutting-edge electronic devices that meet the demands of the modern world.