PCB assembly services are a crucial part of the electronics industry. PCB stands for printed circuit board, which is a thin board that contains electrical components and connections. PCB assembly is the process of attaching these components to the board, either by soldering or using other methods.

PCB assembly services can offer many benefits to customers who need to produce electronic devices, such as:

1.Saving time and money: PCB assembly services can handle the entire process of designing, manufacturing, testing, and shipping the PCBs, saving customers the hassle and cost of doing it themselves.

2. Ensuring quality and reliability: PCB assembly services have the expertise and equipment to ensure that the PCBs meet the specifications and standards of the customers, and that they function properly and consistently.

3.Providing flexibility and customization: PCB assembly services can cater to the specific needs and preferences of the customers, such as the size, shape, color, material, and functionality of the PCBs.

However, not all PCB assembly services are created equal. Customers should consider several factors when choosing a PCB assembly service provider, such as:

1.Experience and reputation: Customers should look for a PCB assembly service provider that has a proven track record of delivering high-quality PCBs to satisfied customers, and that has a good reputation in the industry.

2. Capabilities and technologies: Customers should look for a PCB assembly service provider that has the capabilities and technologies to handle their PCB requirements, such as the type, quantity, complexity, and speed of the PCBs.

3. Certifications and standards: Customers should look for a PCB assembly service provider that has the relevant certifications and standards to ensure that their PCBs comply with the regulations and expectations of their industry and market.

4. Communication and support: Customers should look for a PCB assembly service provider that communicates clearly and effectively with them throughout the PCB assembly process, and that provides them with adequate support and assistance.

PCB assembly services are an essential part of the electronics industry, but they are not all the same. Customers should do their research and compare different options before choosing a PCB assembly service provider that can meet their needs and expectations.

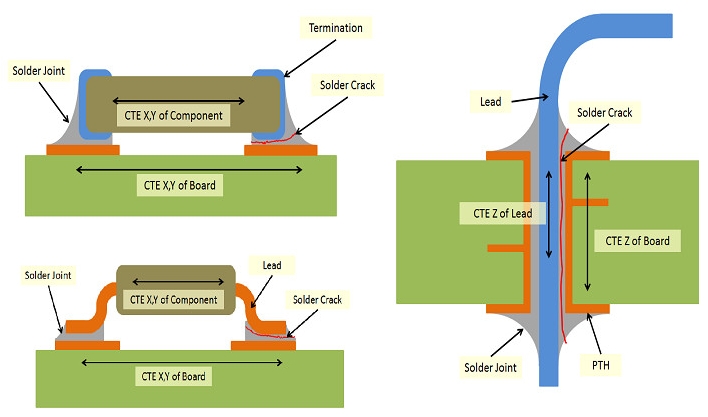

SMT and THT are two methods of mounting electronic components onto printed circuit boards (PCBs). SMT stands for surface mount technology, and THT stands for through-hole technology. The main difference between them is how the components are attached to the PCB.

In SMT, the components have flat co-planar tails or leads that rest on exposed tracks on the surface of the PCB. No holes are needed in the PCB, and solder paste is applied through a stencil to cover the exposed areas. The components are then placed (often by machine) into the solder paste, and then the PCB is heated to reflow the paste.

In THT, the components have leads that pass through holes drilled in the PCB. The leads are then soldered onto pads or lands on the underside of the board, usually with a wave solder process (but also by hand). A recent development of this process has been to change from a plain drilled hole to a plated through hole. Solder paste is applied within the hole, and the lead is pushed through this paste. The whole PCB is then heated to reflow this solder paste – this is called pin-in-paste soldering.

The following images show the difference between SMT and THT components and boards:

The table below summarizes some of the advantages and disadvantages of SMT and THT:

| SMT (Surface Mount Technology) | THT (Through-Hole Technology) |

| Allows for smaller and cheaper PCBs with higher component density | Provides stronger bonds for components that will be under mechanical, electrical, or thermal stress |

| Faster production time with less manual labor | Good for fast prototyping and testing |

| More reliable in conditions of vibration and shake | Requires drilling holes on PCBs, which makes them more expensive, time-consuming, and less compact |

| Less prone to solder issues | Requires soldering on both sides of the PCB, which makes the process more lengthy |

Choosing between SMT and THT depends on your project needs and preferences. You might need to use both technologies in some cases, such as mixed technology (SMT + THT), which can combine the advantages of both methods. You should consult with your PCB assembly service provider to determine the best option for your project.

If you are involved in the electronics industry, you may have heard of PCB assembly services. But what are they, and how can they benefit you?

PCB stands for printed circuit board, which is a thin board that contains electrical components and connections. PCB assembly is the process of attaching these components to the board, either by soldering or using other methods.

PCB assembly services are companies that offer to handle the entire process of designing, manufacturing, testing, and shipping the PCBs for customers who need to produce electronic devices.

Some of the benefits of using PCB assembly services are:

1.They can save you time and money: By outsourcing the PCB assembly process to a professional service provider, you can avoid the hassle and cost of doing it yourself. You can also focus on your core business activities and leave the technical details to the experts.

2.They can ensure quality and reliability: PCB assembly services have the expertise and equipment to ensure that the PCBs meet your specifications and standards, and that they function properly and consistently. They can also perform quality checks and tests to verify the performance and durability of the PCBs.

3.They can provide flexibility and customization: PCB assembly services can cater to your specific needs and preferences, such as the size, shape, color, material, and functionality of the PCBs. They can also offer different options and solutions to suit your budget and timeline.

However, not all PCB assembly services are created equal. You should consider several factors when choosing a PCB assembly service provider, such as their experience, reputation, capabilities, technologies, certifications, standards, communication, and support.

PCB assembly services are an essential part of the electronics industry, but they are not all the same. You should do your research and compare different options before choosing a PCB assembly service provider that can meet your needs and expectations.

If you are working on a project that requires custom PCBs, you might need to hire a PCB assembly service to attach the electronic components to the printed circuit boards. However, not all PCB assembly services are the same, and choosing the wrong one can result in low-quality, expensive, or delayed PCBs. To avoid these problems, you should consider the following factors when choosing a PCB assembly service:

1. Quality: This is the most important factor, as it determines the functionality and reliability of your PCBs. You should look for a PCB assembly service that has certified and experienced technicians, modern and well-maintained equipment and tools, strict quality control measures, and thorough testing procedures. You should also ask for samples of their previous work, check their certifications and accreditations, and read customer reviews to verify their quality.

2. Cost: This is another important factor, as it affects your budget and profitability. You should look for a PCB assembly service that offers competitive and transparent pricing, with no hidden fees or extra charges. You should also compare different quotes from different services, and look for discounts or special offers for bulk orders or long-term partnerships.

3.Speed: This is a factor that depends on your project timeline and urgency. You should look for a PCB assembly service that has a reliable supply chain, an efficient production process, a fast turnaround time, and a flexible delivery schedule. You should also check their lead time and delivery options, and look for services that offer express or rush orders if you need your PCBs urgently.

3. Capabilities: This is a factor that depends on your project specifications and requirements. You should look for a PCB assembly service that has a wide range of capabilities, such as surface mount technology (SMT), through-hole technology (THT), mixed technology (SMT + THT), single-sided or double-sided assembly, rigid or flexible PCBs, high-density interconnect (HDI) PCBs, etc. You should also check their capabilities and limitations, and look for services that can meet your specific needs.

Choosing a PCB assembly service can be challenging, but it can also be rewarding if you find the right one. By following these tips, you can find a trustworthy and professional PCB assembly service that can provide you with high-quality PCBs at a reasonable cost and speed.