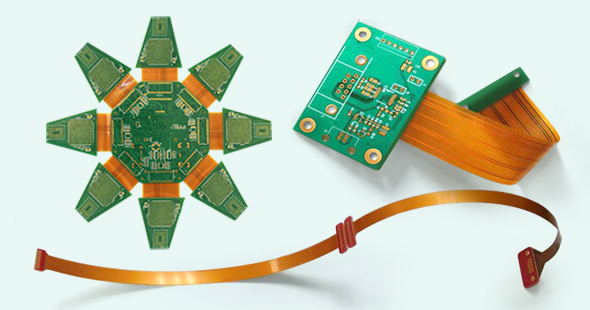

Rigid flex PCBs combine rigid areas and flexible circuits in a single board, offering versatility and space-saving benefits in electronic devices. The integration of both rigid and flexible components allows for intricate designs that can adapt to various form factors and applications.

Carefully plan the layout of rigid and flex areas to optimize functionality and reliability.

Ensure a seamless transition between rigid and flexible sections to minimize stress points.

Determine the appropriate bending radius for flexible areas to prevent mechanical failures.

Choose materials with suitable flexibility to accommodate the required bending radius.

Strategically place plated through holes to facilitate interconnection between rigid and flex components.

Maintain proper clearance and aspect ratios for reliable connections.

Implement a solid ground plane to ensure proper signal integrity and EMI shielding.

Consistent grounding throughout the board is essential for optimal performance.

Adhere to design rules specified by your PCB manufacturer to ensure manufacturability.

Consider factors such as trace width, spacing, and via placement for efficient PCB production.

When you are working on designing rigid-flex PCBs, it is extremely important to find the right balance between the rigid and flexible areas so that you can meet the specific requirements of your application. By carefully considering this balance, you can ensure that your PCB will effectively perform its intended functions without any issues.

1. Flex circuits provide users with a notable advantage when it comes to creating electronic devices that are both compact and flexible.

2. These circuits possess a remarkable level of flexibility, making it possible to design products that can be bent and manipulated without compromising their functionality.

3. By incorporating flex circuits into the construction of electronic devices, manufacturers can create products that are not only sleek and compact but also highly versatile in terms of form and shape.

4. This versatility opens up a wide range of possibilities, enabling the development of innovative and convenient devices that can adapt to different environments and user needs.

5. Thanks to flex circuits, the potential for creating unique and dynamic electronic devices is greatly enhanced.

Rigid-flex printed circuit boards (PCBs) have become increasingly popular in the world of electronics due to their flexible and versatile nature. They provide a practical and efficient solution by combining both rigid and flexible circuits within a single board. This innovative design allows for greater adaptability and customization when integrating electronic components into various applications.

Rigid-flex PCBs are highly sought after as they offer the best of both worlds, enabling engineers and designers to optimize space utilization, minimize weight, and enhance overall product performance. By seamlessly merging rigidity and flexibility, these PCBs have revolutionized the electronic industry.

Flex printed circuit boards (PCBs) offer distinctive benefits when it comes to electronic design, particularly in situations where flexibility and compactness play a vital role. These PCBs possess qualities that set them apart from traditional rigid boards, making them highly valuable in various applications. Whether it's for wearable devices, curved displays, or space-constrained systems, the flexibility and compact nature of flex PCBs enable designers to create innovative solutions that are both versatile and efficient.

Flexible circuits, also known as flex circuits, provide a practical and trustworthy option for connecting electronic components. They are especially useful in situations where standard rigid printed circuit boards (PCBs) may not be the best fit. With their cost-effectiveness and reliability, flexible circuits offer an excellent solution for electronic interconnections.

Designing rigid flex printed circuit boards (PCBs) necessitates a meticulous equilibrium between functionality, ease of manufacturing, and overall performance. Achieving the perfect blend of these aspects is essential for the successful creation of rigid flex PCBs.

In conclusion, rigid flex PCBs represent a cutting-edge solution for modern electronic design. Implementing these guidelines will empower you to design efficient and high-performance rigid flex PCBs. Embrace the flexibility and versatility of rigid flex PCB technology to unlock new possibilities in electronic design and manufacturing.