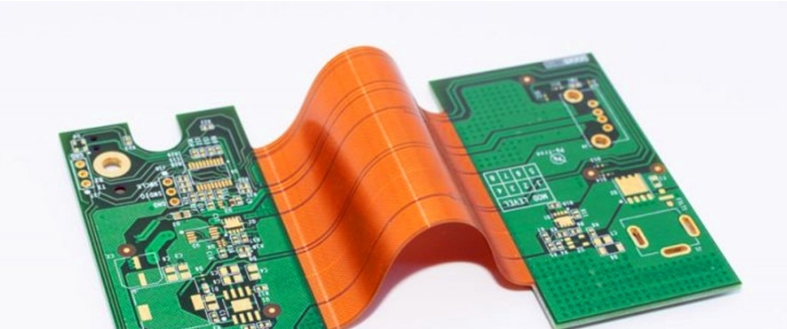

In the world of electronics, there are new types of circuit boards called rigid-flex PCBs. These boards mix both flexible and rigid parts to make strong and adaptable circuits. This article will explain these boards in simple terms, focusing on how they are made, why they are useful, and where they are used.

Rigid-flex PCBs are special boards that can be both flexible and solid. This feature enables the users to accomplish tasks that conventional boards are unable to perform, thereby enhancing their productivity and efficiency. They are great for making electronic systems that need to be tough yet able to bend or fit into tight spaces.

Flexible circuits can bend and fit into odd shapes. They are handy for electronics that need to move or squeeze into tight spots. Combining both flexible and rigid elements gives the best of both worlds.

Making rigid-flex boards is a careful process. It involves putting together flexible and solid parts perfectly. Specialists handle each step with care to ensure the boards are strong, reliable, and work well.

These boards can have multiple layers, which means more space for circuits. Having many layers helps with making complex designs and reduces electrical interference, making the circuits work better.

In order to put together these boards, it is necessary to attach the electronic components with utmost care. Soldering the parts and testing everything are crucial steps. Checking that the boards work right is vital before using them.

Choosing the right materials for the boards is key. Flexible parts often use special films that can twist without breaking. The solid parts are usually tough FR4 boards for stability.

Designing these boards needs attention to detail. Factors like how the board can bend, where parts go, and how signals move need to be thought out well. Good communication between designers and builders is important for successful projects.

Making these boards needs precise work with advanced equipment and careful checks. Experts handle drilling, copper plating, soldering, and adding components step by step. This ensures the boards are strong and work correctly.

These special boards find uses in many fields, from planes to medical gear. They are favored for their ability to withstand tough situations and fit well in small spaces. Their reliability and compact size make them great for critical applications.

New ideas keep improving how we make rigid-flex circuits. Innovations like two-sided flexible circuits and smart components help create more efficient and reliable systems. These advancements lead to smarter and smaller electronics.

The durability of these boards is key for electronics that face rough conditions. By blending sturdy materials and flexibility, these boards last longer and work well even under tough situations. This ensures electronics stay reliable for longer.

Adding a protective layer called a solder mask shields the circuit from harm. Various techniques like liquid or dry film masks help ensure good coverage and strong connections during assembly. Doing this right makes the boards more reliable.

Board technology blends the ability to bend and stay strong, creating boards that can adjust to various shapes while staying reliable. This combination is what makes rigid-flex PCBs versatile and fit for many electronic needs.

Wrapping up, rigid-flex PCBs bring together flexibility and durability to create adaptable and robust electronic solutions. By harnessing the strengths of both flexible and solid circuits, designers can craft compact, sturdy, and versatile electronic systems for diverse applications. As technology develops, the future promises even more exciting possibilities for rigid-flex circuit design and performance enhancement in the ever-evolving world of electronics.