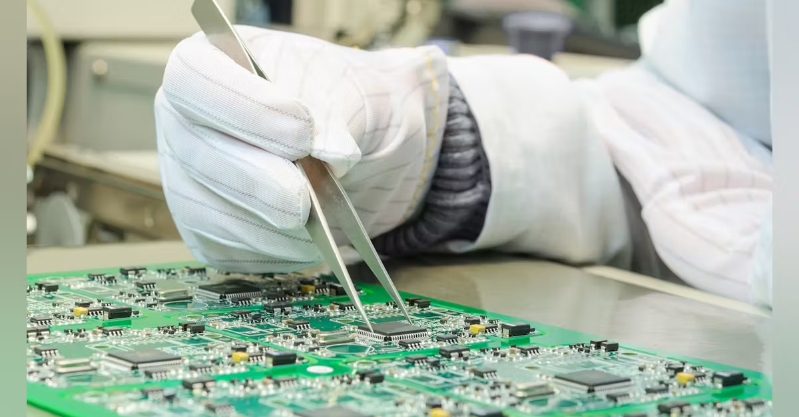

Printed Circuit Boards (PCBs) are the backbone of modern electronics, residing within every gadget we use, from smartphones to satellites. Low-volume PCB assembly fills the gap between prototype and full-scale production for those who need specialized, smaller quantities.

PCBs are essential in modern electronics, serving as the foundation for electronic interconnections in devices. They are especially important when only a small batch of them is needed.

Low-volume PCB assembly is the production of PCBs in limited quantities, ideal for prototyping, custom projects, or the early stages of product launch.

Circuit boards are complex and intricate, much like a city map, connecting various electronic components.

High quality is critical in low-volume production, as a single error can lead to significant malfunctions and resource wastage.

Prototyping is a vital step in bringing a PCB concept to life and verifying design viability before scaling up.

Design accuracy and component selection are key challenges in the prototyping stage that require careful attention to detail.

Experience, flexibility, and the ability to handle complex PCBs are crucial factors when choosing a PCB assembly partner.

Service providers specializing in low-volume PCBs are best equipped to handle the unique challenges of small-scale production.

Double-sided PCBs offer complex circuitry for multifaceted low-volume projects without significantly increasing board size.

Emerging assembly techniques offer increased flexibility and efficiency for low volume PCB production.

Optimizing each phase of production is essential for efficiency in small-batch orders.

It is important to be aware of and navigate common pitfalls in low-volume production to ensure a smooth assembly process.

Automation, miniaturization, and eco-friendly production are trends influencing both high-volume and low volume PCB assembly.

With rising environmental concerns, sustainable practices are becoming essential in low volume PCB production.

Low volume PCB assembly combines precision, agility, and economic sense, supporting innovators and developers as technology advances.

It is the assembly of components onto PCBs in small quantities, typically for prototypes or small-scale production.

Double-sided PCBs allow for more complex circuits without increasing board size.

Prototyping is essential for testing functionality and identifying issues before mass production.

Yes, many services offer production for single prototypes.

Low volume production can reduce waste and integrate sustainable practices to minimize environmental impact.