The world of electronic devices experiences constant evolution, with one notable development being the increasing use of multilayer PCBs in manufacturing. These board designs have layers that increase the circuit's complexity and efficiency, reflecting the digital age's multifaceted spirit.

Consider the process of building a multilayer PCB as similar to the construction of a skyscraper. Each floor of the building represents a specific layer that serves a unique purpose in enabling complex circuit designs, providing power and ground layers. For achieving an optimal balance in the structure, the structure requires an odd number of layers. This is because multilayer PCBs offer several advantages over single or double-sided boards.

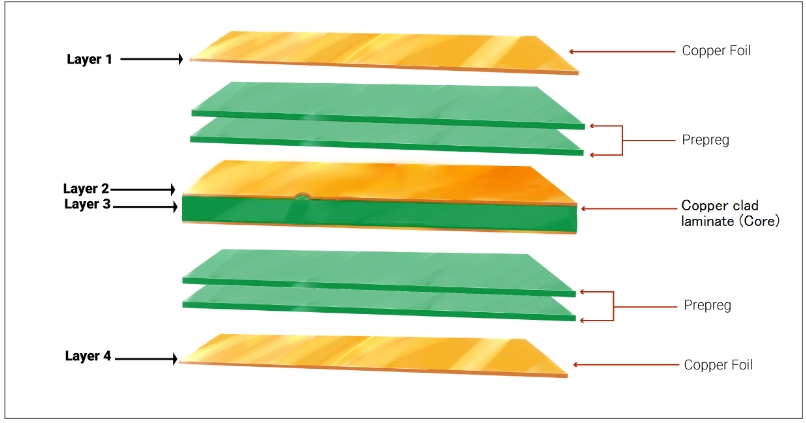

Just as a well-designed building needs a strategic layout, so does a multilayer PCB. The unique layer stack-up, comprising an outer layer, insulating material, and the power and ground planes, influences the board's overall reliability and performance.

Multilayer PCBs offer numerous advantages, such as reduced size, improved functionality, and enhanced signal quality. Despite the relatively high cost compared to double-sided PCBs, these benefits often outweigh the investment.

Like the foundation of a tower, the trace impedance in a PCB serves as the basis for the electronic transmission within the board. Any imbalance can disrupt the circuit's integrity and cause data transmission errors.

Why it Matters

Maintaining consistent impedance is essential to prevent disruptive signal reflections, much like well-maintained traffic movement avoids accidents.

Heat management is critical in multilayer PCB design as these boards often work under high temperature and pressure conditions. A well-designed PCB effectively dissipates heat, preventing component damage or system failures.

Role of Heat Dissipation

Heat dissipation is to PCBs what ventilation systems are to buildings - vital for maintaining acceptable operating conditions to ensure longevity and performance.

Just like architects need proper software to design buildings, PCB designers require reliable PCB designing software. These applications accommodate the complexities associated with designing multilayer PCBs, from layer arrangement to circuit pathway planning.

Common mistakes to avoid while designing multilayer PCBs include neglecting manufacturability and overlooking physical constraints. A comprehensive planning approach is essential to avoid future problems related to production and functional aspects.

Improvement isn't an overnight process; it's a journey fuelled by continual learning and practice. Gaining a deep understanding of guidelines, potential mistakes to avoid, and effective techniques will enhance your skills in multilayer PCB design.

1.What defines a multilayer Printed Circuit Board (PCB)?

A multilayer Printed Circuit Board (PCB) is an electrical circuit made by layering two or more single-sided or double-sided boards with insulating material between them. Adding additional layers to a single board significantly enhances electronic device performance by enabling the addition of more circuitry.

The individual boards (layers) within the multilayer PCB are connected via tiny holes called vias, which facilitate electrical connection between the different layers. Multilayer PCBs can have varying numbers of layers, ranging from four to over 40 for advanced technology applications.

Multilayer PCBs are prominently used in high-technology and high-speed electronic applications due to their advantages in increased connection density, better signal integrity, compactness, and reduced system noise.

2.Why are multilayer PCBs important?

Multilayer PCBs (Printed Circuit Boards) are integral to modern electronics, and they have multiple advantages that have paved the way for innovations and advancements in technology.

High-Density Connections: Multilayer PCBs can accommodate more connections and conductors within a smaller form factor. This is essential for complex electronic devices where space is often a critical constraint.

Improved Signal Integrity: By dedicating specific layers as power and ground planes, multilayer PCBs can offer a shorter, more direct path for signals, greatly improving signal integrity and speed.

Reduced Size and Weight: Since multilayer PCBs can encapsulate multiple layers of circuits into one board, the overall size and weight of the product can be substantially reduced. This makes multilayer PCBs ideal for small and mobile electronic devices.

Reduced System Noise: Multilayer PCBs can reduce electromagnetic interference (EMI), ensuring less system noise and interference by using the correct layout of power and ground layers.

Flexibility: Multilayer PCBs can be created in various sizes and configurations, offering flexibility that allows designers to meet specific requirements of advanced electronic applications.

Increased Durability: The intertwined and encapsulated design of multilayer PCBs adds structural integrity, making the devices more robust and durable.

Given these benefits, multilayer PCBs are crucial for modern electronic devices – from smartphones and computers to medical equipment and crucial aerospace applications.

3.What is impedance control in a PCB?

Impedance control in a Printed Circuit Board (PCB) refers to the design process aiming to match the source signal impedance with the load impedance, facilitating optimal signal transmission and reducing loss or distortion.

In PCB design, impedance is the measure of opposition that a circuit presents to a current when a voltage is applied. It incorporates both resistance (resistive properties) and reactance (capacitive and inductive properties). The exact value of impedance depends on factors such as the dielectric constant of the board material, the trace width, thickness, spacing, and the trace routing geometry.

When dealing with high-speed digital or high-frequency analog circuits, the impedance of signal paths, known as "controlled impedance lines," must be kept consistent. Any mismatch can cause signal reflections, leading to signal degradation or data loss. This becomes especially crucial in multilayer PCBs, where different layers can have varying impedances due to the unique stack-up of layers.

Hence, impedance control is an essential part of the PCB design process for high-frequency circuits to ensure a successful and efficient signal transmission across the board.

4.Why is thermal management necessary in PCB design?

Thermal management is a crucial aspect of Printed Circuit Board (PCB) design due to several reasons:

Prevent Overheating: Electronic devices generate heat when in operation. Without proper heat dissipation, components can overheat, leading to decreased performance, shortened lifespan, or immediate physical damage.

Maintain Stability: Heat influences the impedance of a PCB. As temperature increases, resistance also increases, altering the electrical characteristics of the board and the behavior of the embedded components. This can lead to circuit instability and deviations in the expected performance of the device.

Avoid Thermal Stresses: High temperatures and rapid temperature fluctuations create thermal stresses in the PCB material, which can cause warping, component displacement, solder joint cracking, and other forms of physical damage.

Ensure Reliable Operation: High temperature affects both active and passive electronic components. Semiconductors, for instance, can face reduced lifespan, increased leakage current, and altered threshold voltages. Thermal management can help to keep these issues in check, ensuring the reliable operation of the device.

Protect Other Components: Heat produced in one area of a PCB can affect adjacent components or areas not designed to sustain higher temperatures. Efficient thermal management can maintain heat within acceptable limits, protecting all parts of a product from thermal damage.

Effective thermal management strategies in PCB design include the use of thermal vias for heat transfer, heat sinks, air ventilation, and careful placement of heat-generating components. In advanced applications, active cooling solutions like fans, circulators, or even liquid cooling might be necessary. Therefore, thermal management forms an integral part of PCB design and is a key factor in ensuring the longevity and reliability of electronic devices.

5.What are common mistakes in multilayer PCB design?

Multilayer Printed Circuit Board (PCB) design offers many advantages, but it can also be a complex process. There are several common mistakes designers can make:

Poor Stack-Up Design: Effective stack-up design is essential for signal integrity and EMI (Electromagnetic Interference) mitigation in a multilayer PCB. A poorly designed stack-up leads to imbalanced capacitance, impact signal transition, crosstalk, and ultimately product failures.

Incorrect Impedance Control: Overlooking impedance control often leads to signal integrity issues. Designers need to match trace impedance correctly with source and load impedances to prevent signal degradation and loss.

Inadequate Thermal Management: Neglecting proper heat dissipation strategies can lead to overheating, affecting the performance and reliability of the PCB.

Ignoring DFM (Design For Manufacturability) Guidelines: Not adhering to manufacturer's guidelines can lead to difficulties during the manufacturing process. This includes ignoring the minimum trace widths, via sizes, hole drilling, and clearances provided by the PCB manufacturer.

Poor Component Placement: Component placement impacts signal integrity, thermal management, and overall board functionality. Poor placement can also complicate routing, soldering, and assembly processes.

Insufficient Power and Ground Plane Utilization: Power and ground planes play a critical role in signal coupling and power distribution in a multilayer PCB. Insufficient or improper use can lead to power integrity issues and unwanted noise.

Lack of Design Rule Checking: Forgetting to run regular Design Rule Checks (DRCs) could mean that small errors become big problems later on.

Not considering EMI/EMC (Electromagnetic Compatibility): Ignoring EMI can cause disturbances, performance degradation or even system failure.

Improving your understanding of these potential pitfalls and making an effort to avoid them can help streamline your design process and ensure a more reliable and efficient multilayer PCB.