Ever wondered how electronic gadgets come to life? The concept becomes a reality through a procedure known as Rapid PCB Prototyping. This technique is transforming the electronics industry, enabling the production of cost-effective, high-performance, and custom-made devices.

Quick Turn Prototyping, a prominent method applied extensively within the realm of electronics, has exhibited its capacity to expedite the creation of functional prototypes originating from established designs, particularly in regards to circuit boards. This technique, renowned for its speed and efficiency, has transformed the way we approach development in this field. Notably, the utilization of this approach ushers in a new level of efficacy in swiftly reproducing and bringing to life functional prototypes, which can further affirm the reliability and effectiveness of the initial design.

Inarguably, Quick Turn Prototyping is embedded within the initial, and undoubtedly critical, phases of the development life cycle in electronics. The importance it holds isn't to be undermined, as it provides a foundational ground for subsequent steps that build upon it. This stage involves various iterative processes aimed at refining and enhancing the design in order to ensure its performance meets or even surpasses initial expectations.

What makes these stages so imperative to acknowledge, is the fact that these are the periods wherein testing phases come into play. These testing phases, often marked by meticulous assessments and stringent evaluations, are vital in determining the ultimate accomplishment of the project. It’s during these testing procedures where the prototype - that was quickly and efficiently generated through Quick Turn Prototyping - gets put through a series of rigorous evaluations. This practice is pivotal as it certifies the design's feasibility and minimizes the chances of failure when moved to mass production.

In essence, the role played by Quick Turn Prototyping during these stages offers profound implications on the overall advancement of the project in the electronics field, ensuring the initial design swiftly materializes into a tangible, functional device. Herein, the purpose is to not only validate the design in the quickest time possible but also impart a level of certainty that it can successfully undergo and pass the scrutiny of testing, leading to a meaningful contribution to the wider world of electronics.

You may find yourself questioning, why is the fast and efficient process of prototyping so vitally important to our everyday workings? Imagine for a moment, this manufacturing method as a catalyst, an agent of change, characterized by its dependency on both speed and meticulous accuracy, creating a fruitful environment for innovation.

This expeditious process fundamentally acts as an enabling tool, providing the key to a door that would otherwise remain closed. It presents engineers and other professionals with a medium to swiftly recognise the possible design flaws or mistakes that might have been overlooked in the initial stages of their work, the very early beginnings of the design creation process itself.

Furthermore, not only does it allow these individuals to take immediate notice of such errors, but its value is truly illuminated by what follows this. The ingenious strategy empowers them to correct, modify, and improve upon these faults, therefore enhancing the overall quality and effectiveness of their finished work, be it a product, a service, or even an idea.

In a nutshell, quick turn prototyping stands as an indispensable tool by fostering a culture of continuous improvement and ascertaining an overall better quality, thus propelling design processes to greater heights.

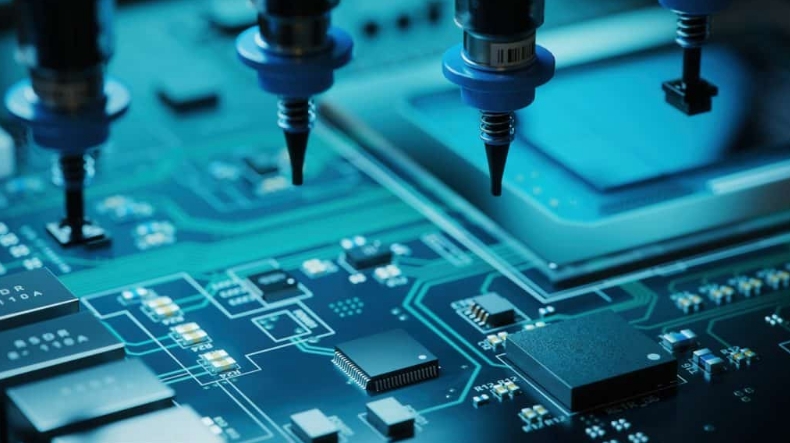

Quick-turn Prototyping commences with a comprehensive electronic design. In the modern era, developers use cutting-edge software to create and model the functioning of the PCB (Printed Circuit Board). This step demands absolute attention to detail for maintaining the practicality of the model.

After designing it's time for fabrication. Here, developers bring the PCB design to life utilizing various techniques like milling, etching, and drilling.

The method allows early error detection, reducing the 'turnaround time' for extensive revision. The adage suggests that time equates to financial value.

Remember that addressing issues at the development stage is economically prudent compared to handling hefty product recalls or discontented customers later.

Rapid PCB Prototyping Services significantly enhance the quality of electronics. Prompt iterations lead to refined design and superior performance.

The creation of robust electronic components for these sectors primarily relies on Prototype boards.

In the healthcare domain, the necessity for reliable and safe solutions is high, and that's where our PCB Prototyping services come in.

Even though it is undeniable that there are numerous advantages associated with Rapid PCB Prototyping Services, they are not without their own unique set of challenges. One of the main difficulties they contend with is the fast-paced and continually evolving landscape of technology. With technological advancement sprinting forward at full speed, keeping up is often a challenge.

Furthermore, there is an issue that pertains to the restrictions of materials. The nature of these services requires specific types of elements that might not always be readily available. Sometimes, these resources can be constrained which in turn, impacts the overall process.

In addition to these challenges, there is a constant requirement for absolute precision throughout every single second of operation. This is because even the slightest error can have massive impacts on the prototype being developed. As such, maintaining round-the-clock accuracy, avoiding mistakes at every stage of the process, is something that these services are always striving towards, adding yet another level of complexity to their operation.

Therefore, despite the inherent advantages and the immensely beneficial outcomes, the path traversed by Rapid PCB Prototyping Services is studded with considerable challenges such as continuously shifting technological landscapes, the potential constraints on essential materials, and the unwavering need for persistent precision and accuracy.

To sum up, PCB Prototyping is pushing us towards a future filled with efficient, dependable, and speedy electronics development. It mirrors a magical catalyst embedded within each electronic breakthrough, amplifying both ingenuity and the rate of progression.

A swift process turning theoretical electronics designs into functional Prototype boards.

It helps with early identification and repair of design flaws, ensuring high-quality and cost-effective electronic products.

Speeds up development, cuts down costs, and ensures quality products.

Used across various sectors like aerospace, defense, and medical devices.

A few challenges include keeping pace with technology evolution, dealing with material constraints, and maintaining precision continuously.