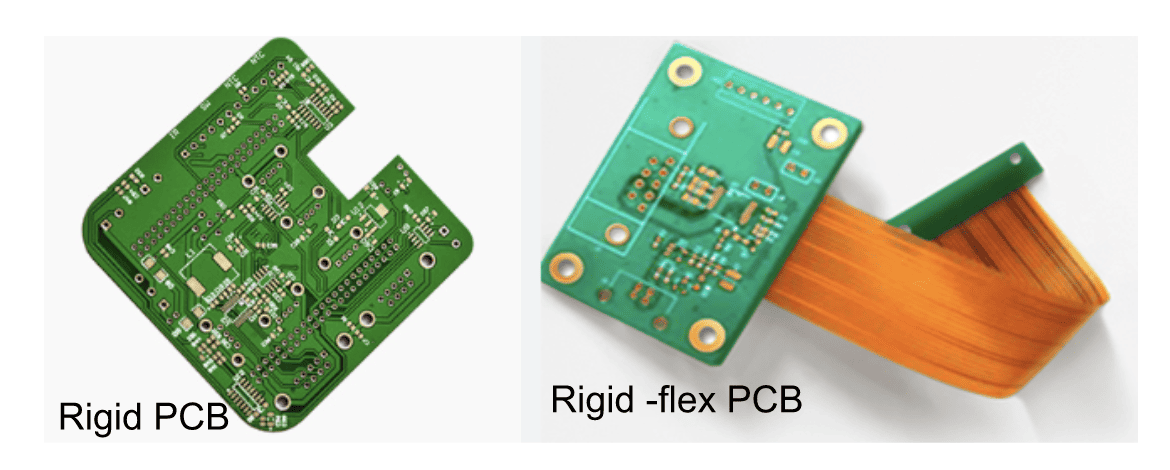

Rigid flex PCBs are boards that use a combination of flexible and rigid board technologies in an application. Most rigid flex boards consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending on the design of the application .

The flexible layers are usually made of polyimide or polyester-based materials, while the rigid layers are typically made of FR-4 or other epoxy-based materials. The flexible and rigid layers are connected by conductors and plated through holes that allow electrical signals to pass through them.

Rigid flex PCBs can have different configurations, such as:

- Single-sided rigid flex: A single layer of flexible circuit is attached to a single layer of rigid board on one or both sides.

- Double-sided rigid flex: Two layers of flexible circuit are attached to a single layer of rigid board on one or both sides.

- Multilayer rigid flex: Multiple layers of flexible circuit are attached to multiple layers of rigid board on one or both sides.

- Rigid-flex-rigid: A sandwich structure where a flexible circuit is enclosed between two rigid boards.

Flexible PCBs are boards that have only flexible materials, usually polyimide or polyester-based. They can be single-layer, double-layer or multilayer boards. Flexible PCBs can be bent, folded, twisted, or rolled to fit into various shapes and sizes. They are ideal for applications that require high-density wiring, dynamic flexing, or limited space.

Rigid flex PCBs differ from flexible PCBs in several ways, such as:

- Rigid flex PCBs have both flexible and rigid materials, while flexible PCBs have only flexible materials.

- Rigid flex PCBs can provide better mechanical support and protection for the components and traces, while flexible PCBs may require additional support or reinforcement.

- Rigid flex PCBs can offer higher circuit density and routing complexity, while flexible PCBs may have some limitations in terms of layer count and via options.

- Rigid flex PCBs can achieve better signal integrity and electrical performance, while flexible PCBs may suffer from higher impedance mismatch, parasitic capacitance, and crosstalk.

What Are the Benefits of Rigid Flex PCBs?

Rigid flex PCBs offer many advantages over traditional PCBs, such as:

Improved reliability: Rigid flex PCBs eliminate the need for connectors, cables, and solder joints that can fail or degrade over time. They also reduce the stress on the components and traces due to bending and vibration.

Reduced size and weight: Rigid flex PCBs allow for more compact and lightweight designs by enabling three-dimensional configurations and eliminating excess materials and components.

Enhanced performance: Rigid flex PCBs provide better signal integrity and electrical performance by reducing impedance mismatch, parasitic capacitance, and crosstalk. They also improve heat dissipation and thermal stability by allowing for better airflow and heat transfer.

Cost savings: Rigid flex PCBs can lower the overall cost of ownership by reducing the number of parts, assembly time, testing time, and maintenance costs.

Rigid flex PCBs can be used in a wide range of applications across various industries, such as:

Aerospace and defense: Rigid flex PCBs can withstand harsh environments and meet stringent military specifications. They can be used in applications such as satellites, missiles, radars, avionics, drones, etc.

Medical: Rigid flex PCBs can provide high reliability and biocompatibility for medical devices. They can be used in applications such as pacemakers, hearing aids, implants, endoscopes, etc.

Automotive: Rigid flex PCBs can offer high performance and durability for automotive electronics. They can be used in applications such as infotainment systems, navigation systems, sensors, cameras, etc.

Consumer electronics: Rigid flex PCBs can enable innovative and ergonomic designs for consumer electronics. They can be used in applications such as smartphones, tablets, laptops, wearables, etc.

If you are looking for a trusted partner for your rigid flex PCB needs, you should contact Rigao Electronics, one of the leading rigid flex printed circuit board manufacturers in China. Rigao Electronicshas over 20 years of experience in providing high-quality flex & rigid-flex PCBs for various industries. They offer quick turnaround time (1-5 days), product reliability (ITAR M26780 and AECA compliant), global certifications (ISO 9001:2015, UL 94V-0, IPC 6013), and competitive pricing. You can visit their website at https://www.rigaopcb.com to get a quote or learn more about their products and services.